WHO WE ARE

WHO WE ARE

Where Precision Meets Purpose. At BM Technology, we are more than just a mold maker – we are the strategic manufacturing partner behind your global ambitions. We transform your concepts into reliable, high-performance tooling through masterful engineering, uncompromising quality, and deep collaboration. From initial design to full-scale production, we ensure every mold is engineered to perfection, powering your innovation and propelling your success.

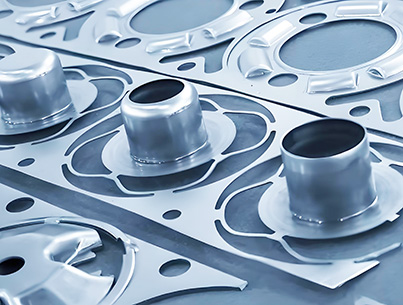

Ultra-Precision Micro-Stamping Die

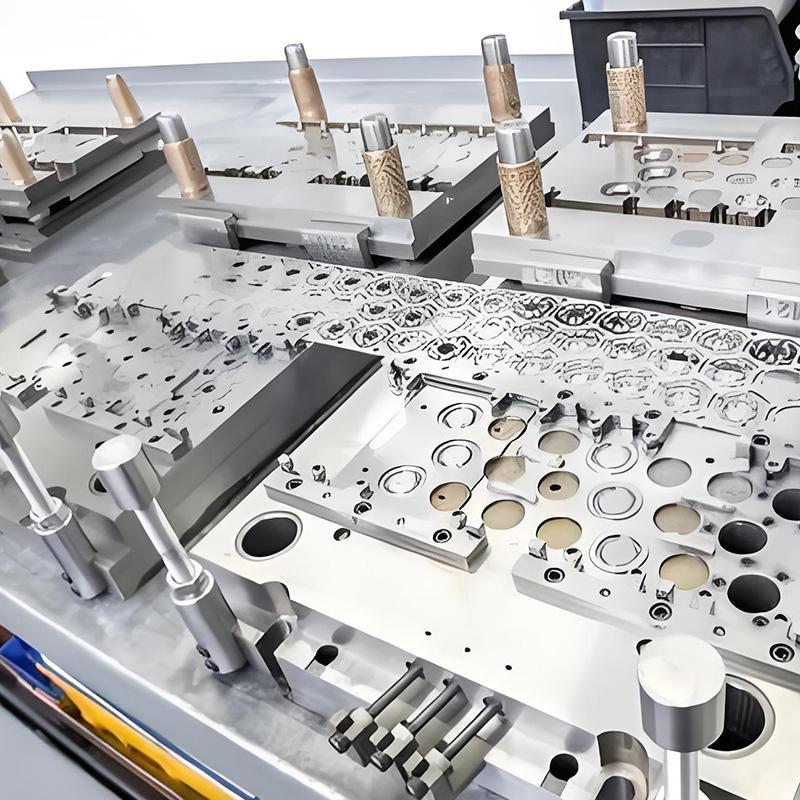

Turnkey Stamping Die System

Your Premier Partner for End-to-End Precision Custom Molds

Rapid Prototype Stamping Die

Low-Volume, High-Mix Custom Die

Long-Life, Heavy-Duty Stamping Die

OUR MISSION

About Us

OUR MISSION

About UsBM MOULD which keeps to contribute to our country in terms of employment and export with the understanding of continuous development by closely following the developments in the world, aims to be one of the leading companies in the world in the molding and machinery sector with high quality and honesty with the Technologies brand.

Our precision modern facilities accommodate tool and stamping projects, from large progressive dies to sheet metal forming. Facilities and the equipment are important, but it all comes down to this - providing you with the tooling solutions you need quickly, accurately and efficiently. Our strong commitment to staying on the cutting edge of technology means we take great pride in always having the best engineering, robust construction, and professional project management. Through continuous improvement, training, and learning we bring you creative ways of making every project successful.

LATEST NEWS

LATEST NEWS

- The key advantages of the blanking die lie in its high efficiency and consistency. It can complete multiple processes like punching and blanking in a single stroke, producing hundreds of parts per minute, significantly boosting production capacity. Meanwhile, relying on a high-rigidity die set, high-quality alloy steel cutting edges, and precise guide mechanisms, the die ensures dimensional stability of parts over millions of strokes, making it crucial for guaranteeing product quality and reducing production costs.2023-02-08

- Typical stamping dies are categorized as single-stage dies and progressive dies. Single-stage dies complete a single process in one set, suitable for large parts or low-volume production. Progressive dies integrate multiple processes in the feeding direction, enabling fully automated, high-speed production, making them the preferred choice for mass production in fields like electronics and automotive.2024-08-08

- A precision injection mold typically consists of the molding system, gating system, temperature control system, ejection system, and structural components. Its design and manufacturing quality directly determine the product's accuracy, appearance, and production efficiency. With the emergence of new materials (like LDS materials, bioplastics) and new processes (such as microcellular foaming, in-mold decoration), the technological scope of injection molds continues to expand.2025-07-17