Status of mold design and manufacturing capabilities

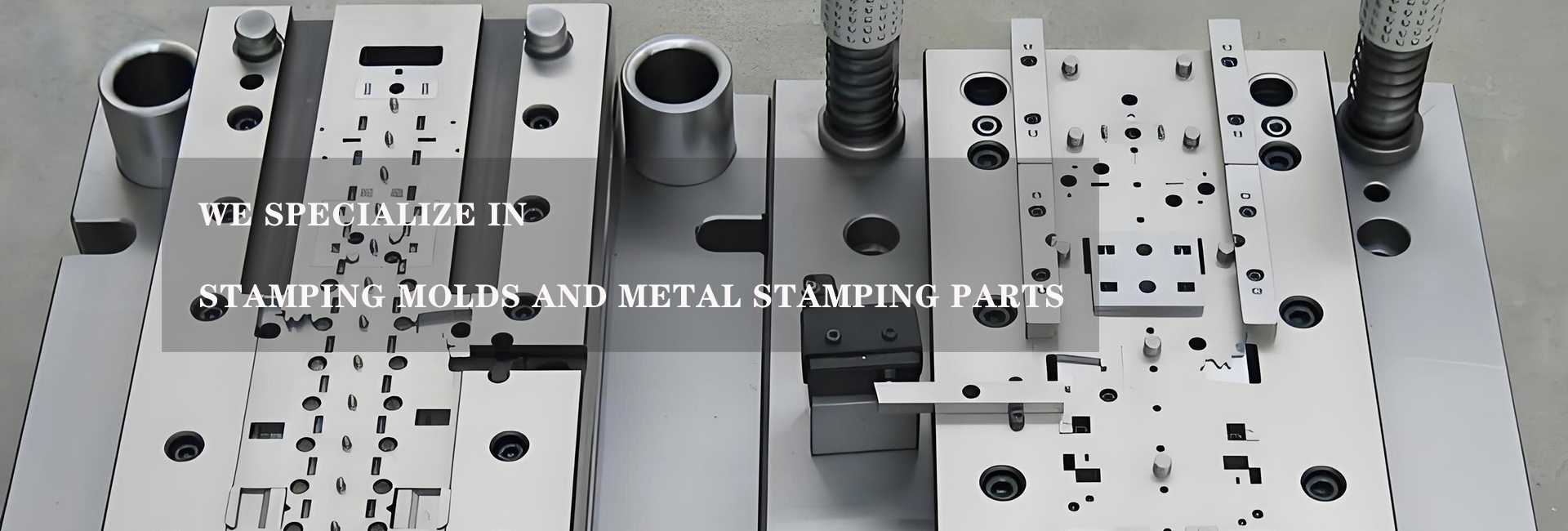

Under the correct guidance of national industrial policies and after decades of efforts, China's stamping die design and manufacturing capabilities have reached a high level, including many modern design and manufacturing technologies such as information engineering and virtual technology, which have been applied in many mold enterprises.

However, there is still a significant gap in China's stamping die design and manufacturing capabilities compared to market demand and international advanced levels. These are mainly reflected in the molds and high-precision stamping dies for high-end cars and large and medium-sized automobile cover parts, which have significant gaps in design, processing technology, and capabilities. Car cover mold has the characteristics of high design and manufacturing difficulty, high quality and precision requirements, and can represent the level of cover mold. Although the design and manufacturing methods and means have basically reached the international level, and the mold structure and function are also close to the international level, a big step has been taken in the localization process of car molds. However, there is still a certain gap compared with foreign countries in terms of manufacturing quality, accuracy, and manufacturing cycle.

The multi station progressive die and multifunctional die, which mark the advanced level of stamping die technology, are precision die varieties that China focuses on developing. A representative example is the multifunctional mold for iron core precision automatic valve plates that integrates mechatronics, which has basically reached the international level.

However, overall compared with foreign multi station progressive dies, there is still a certain gap in manufacturing accuracy, service life, mold structure and function.

The manufacturing technology of automotive panel molds is constantly improving and perfecting, and the use of high-precision and high-efficiency processing equipment is becoming increasingly widespread. The application of high-performance five axis high-speed milling machines and three-axis high-speed milling machines has been increasing. The application of NC and DNC technologies is becoming more and more mature, and can be used for tilt angle machining and ultra precision machining. All of these have improved the precision of mold surface processing, enhanced the quality of the mold, and shortened the manufacturing cycle of the mold.

The surface strengthening technology of molds has also been widely applied. The mature, pollution-free, and cost-effective ion nitriding technology is increasingly recognized, and the application of carbide coating treatment (TD treatment) and many plating (coating) techniques on stamping dies is growing. Vacuum processing technology, solid casting technology, and edge welding technology are becoming increasingly mature. Laser cutting and laser welding technologies have also been applied.