CONTINUOUS DIE

CONTINUOUS DIE

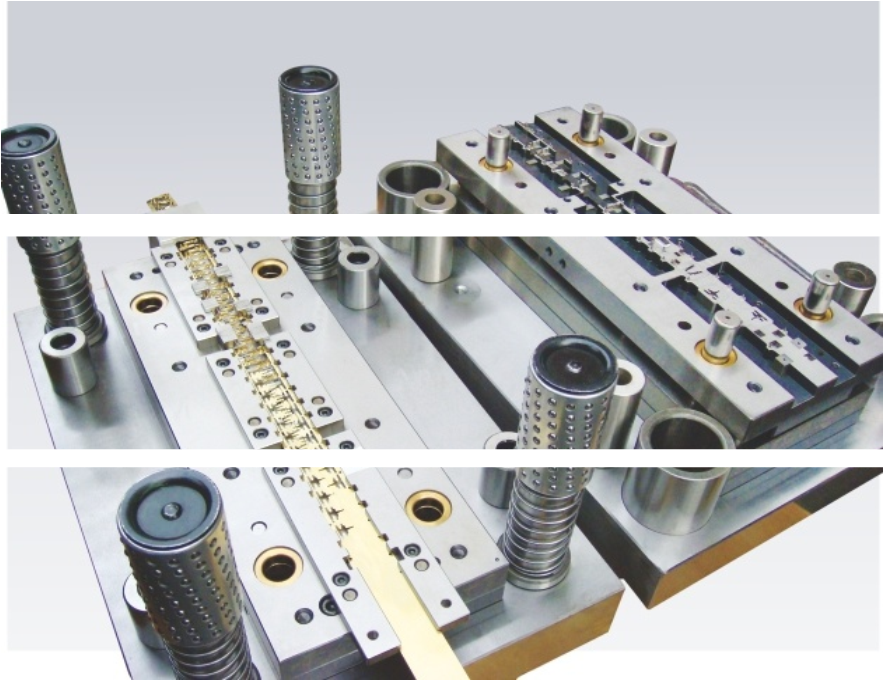

Stamping Process Progressive die stamping uses a type of tooling called a progressive die, which contains multiple stamping stations to carry out simultaneous operations on a sheet metal strip. By combining all the necessary tools into one die set, progressive die stamping is a great solution for high-volume production runs.

Cost

Progressive die and transfer press tooling have higher setup costs compared to stage tooling but offer lower per piece costs. Production Volume It’s important to think of project timelines to determine which method is best. progressive die and transfer press tooling offer medium to fast production speeds. |

MOLD PROCESS

MOLD PROCESS

High quality material selection of mold

A set good mold must have quite high mechanical strength, high temperature hardness, enough toughness, good wear resistance and adhesion resistance, so as to ensure the high precision and high life of the mold

High Temperature Hardening/quenching

High temperature quenching 1100-1150 degrees Celsius, low source temperature quenching 960-1050 degrees Celsius, tempering 550-650 degrees Celsius, two preheating before high temperature quenching, protective measures need to be taken to prevent oxidation

Wire-electrode cutting

To design line cutting route, including the starting point, makes the mold more durable and interprets the excellent process of high quality once again, with a wide range of uses and strong anti-rust performance.

Mold assembly and inspection

Mold parts are assembled after cutting, and assembled for inspection.

PROFESSIONAL ALL KINDS OF METAL STAMPING PARTS

Laser cutting parts, Stamping parts, laser cutting parts, CNC machining parts, automatic lathe machining parts, bending parts, stretching parts, sheet metal parts, drilling parts, CNC lathe parts, turning milling, core parts, computer gong parts, all kinds of copper, iron, aluminum, stainless steel, steel, non-standard parts. |

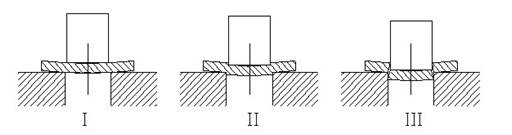

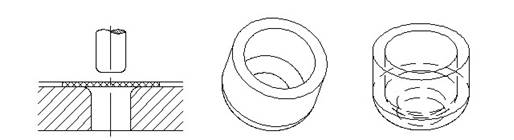

Introduction to the types of molds

Introduction to the types of molds

Conclusion

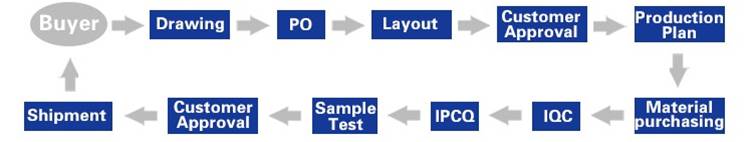

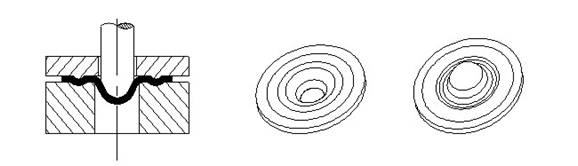

In the hardware production process, usually what we call the stamping automation production line is the progressive die stamping production line, which consists of an decoiler, a straightener, a feeder, a press machine, a mold, and an automatic blanking line. To realize the automatic process of uncoil the coile, leveling the material strip , oiling the strip, stamping into parts, and collecting end parts off the line.During the whole production process, the mold is the most important part of the workpiece’s formation. A mold is a model, used to complete the processes of injection molding, blow molding, extrusion, die-casting, or forging, smelting, stamping, and stretching in industrial production. The common types of mold we use are: stamping molds, plastic molds, blow molds, and die-casting molds.