The principle of stamping

Stamping is a pressure processing method that uses a stamping die to apply pressure to materials on a press at room temperature, causing them to undergo plastic deformation or separation in order to obtain the desired shape and size of parts. This processing method is commonly referred to as cold stamping.

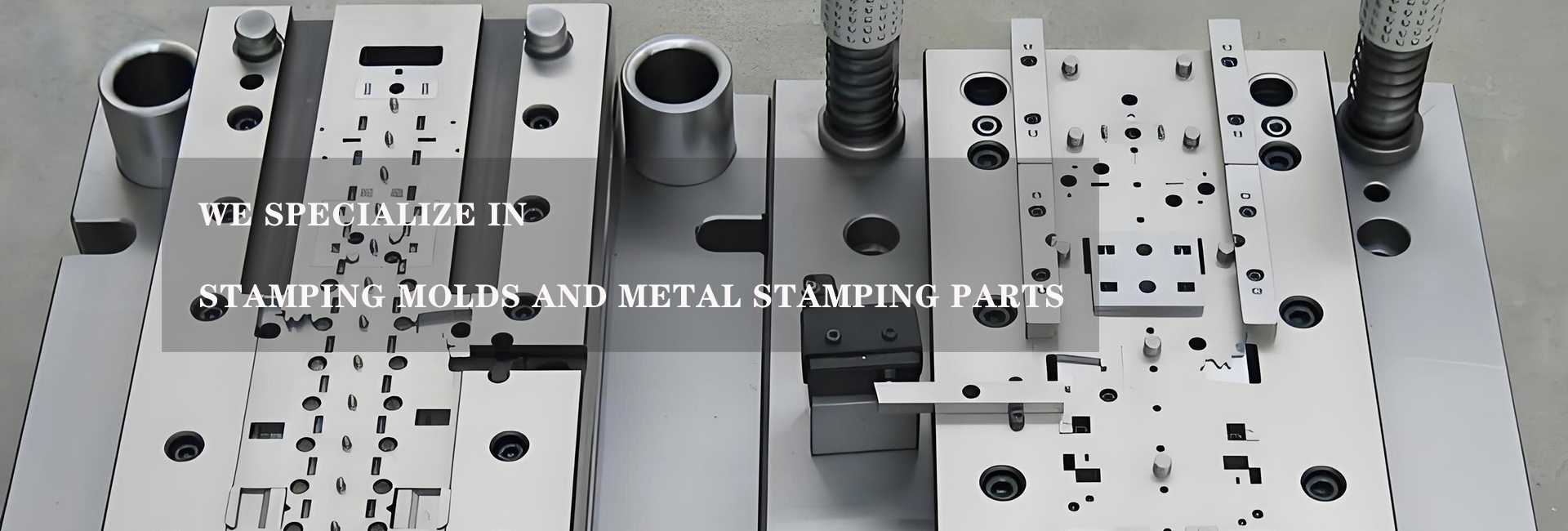

Stamping die is a process equipment used in stamping processing to process materials into workpieces or semi-finished products, and is the main process equipment in industrial production. The production of parts using stamping molds can use rolled steel plates or strips produced in large quantities by metallurgical plants as raw materials, and does not require heating during production, which has the advantages of high production efficiency, good quality, light weight, and low cost. Cold stamping products can be seen everywhere in airplanes, cars, tractors, motors, electrical appliances, instruments, meters, and daily necessities. For example: stainless steel lunch boxes, plates, cans, car coverings, bullet shells, airplane skins, etc. According to incomplete statistics, stamping parts account for about 60% in the automotive and tractor industries, about 85% in the electronics industry, and about 90% in daily hardware products.

A press machine is a mechanical device used to perform pressure processing on materials placed in molds. The commonly used press machines for stamping processing include mechanical press machines and hydraulic press machines.

A stamped part often requires multiple stamping processes to be completed. Due to differences in the shape, dimensional accuracy, production batch, raw materials, etc. of stamped parts, their stamping processes are also diverse, but can be roughly divided into two categories: separation processes and forming processes.

(1) The separation process is the process of separating stamped parts from sheet metal along a certain contour line. For example: cutting, punching, dropping, cutting, trimming, etc.

(2) The process of forming materials that undergo plastic deformation without breaking, in order to obtain parts with certain shapes, sizes, and precision requirements. For example: bending, deep drawing, flanging, bulging, shaping, etc.