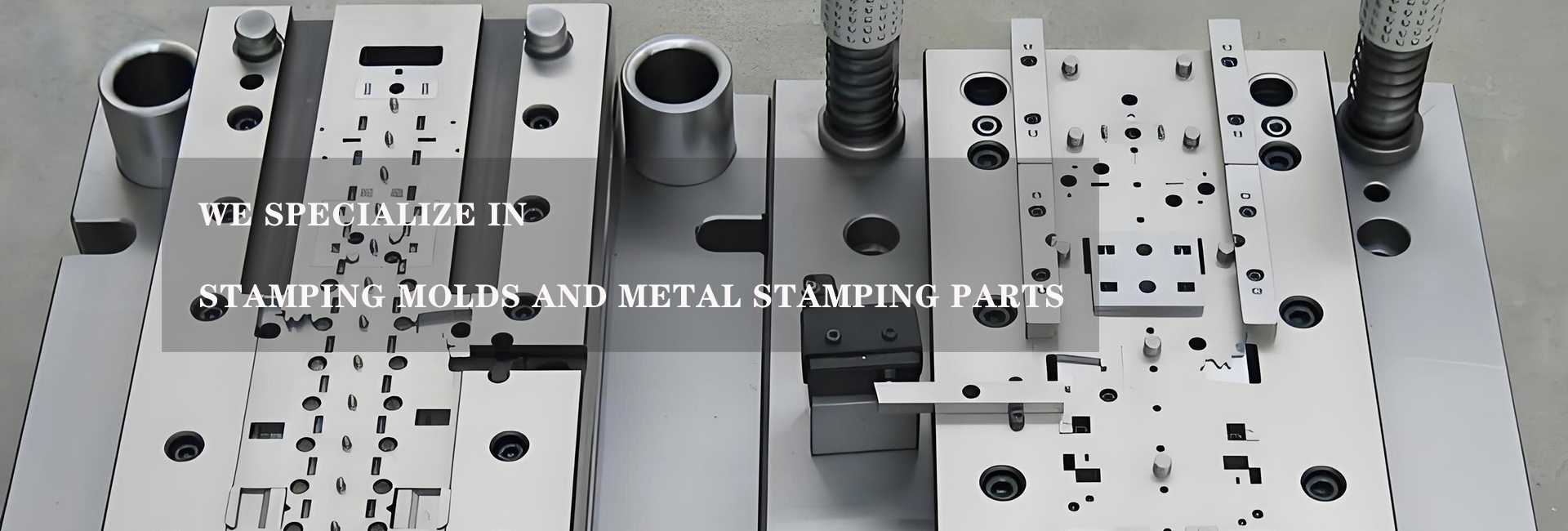

Composition of stamping die

Although the structural forms and complexities of various stamping dies are different, and the parts that make up the dies are diverse, they are always divided into upper and lower dies. The upper mold is usually fixed on the slider of the press through the mold handle, and moves up and down along the press guide rail with the slider. The lower mold is fixed on the worktable of the press. The components and functions of stamping dies are classified as follows:

1. Working parts

It is a part that directly contacts the stamping material and applies pressure to complete the stamping process. The working parts of a stamping die include convex dies, concave dies, and convex concave dies, also known as forming parts, which are the most important parts in the stamping die.

2. Locate the parts

It is to determine the correct position of the material or process part in the die, so that the stamped part meets the qualified quality requirements. The positioning parts that belong to the feeding guidance include guide pins, guide plates, side pressure plates, etc; The positioning parts that belong to the feeding distance include the initial stop pin, stop pin, guide pin, side blade, etc; The positioning parts belonging to block materials or process parts include positioning pins, positioning plates, etc.

3. Pressing and unloading parts

This type of part serves as a pressing material and ensures the removal or pushing (pushing) of waste or stamped parts stuck on the convex mold and concave mold L, to ensure that the stamping work can continue.

The function of the pressure plate is to prevent the billet from moving and bouncing. The function of the unloading plate is to facilitate the unloading and cleaning of waste materials. Usually, the unloading device refers to the process of removing stamped parts or waste materials from the punch; Push and top piece devices refer to the process of removing stamped parts or waste materials from a die. Generally, the part installed in the upper mold is called the push piece, and the part installed in the lower mold is called the top piece.

4. Guiding components

Its main function is to ensure the accuracy of the mutual position between the convex mold and the concave mold, and to ensure that all parts of the mold maintain a good motion state. It is composed of guide columns, guide sleeves, guide plates, etc.

5. Supporting components

It connects and fixes the above-mentioned components to a certain position, or connects the punching die to the press machine. It is the basic component of the punching die. It mainly includes upper mold seat, lower mold seat, fixed plate, cushion plate, mold handle, etc.

6. Tighten the parts

Mainly used to fasten and connect various die parts, such as bolts, screws, round pins, etc. The above guide parts and support parts are assembled and called the mold frame. The mold frame is the skeleton of the entire mold, on which all parts of the mold are fixed and bear all the loads during the stamping process. The upper mold seat of the mold frame is connected to the press slide through the mold handle, and the lower mold seat is fixed to the press worktable with a screw press plate. The precise position between the upper and lower molds is maintained by the guiding device of the mold frame to guide the movement of the convex mold and ensure uniform clearance during the stamping process. The mold frame and its constituent parts have been standardized, and certain technical conditions have been specified for them.

The mold frame is divided into guide column mold frame and guide plate mold frame. The most widely used is the mold frame that uses guide columns and guide sleeves as guiding devices. According to different feeding methods, this standard mold frame includes rear guide column mold frame, middle guide column mold frame, diagonal guide column mold frame, and four guide column mold frame. When designing molds, the correct selection of convex and concave molds is required. The size specifications of the mold frame can be directly selected from the standard based on the perimeter dimensions of the concave mold.