COMPANY INTRODUCTION

COMPANY INTRODUCTION

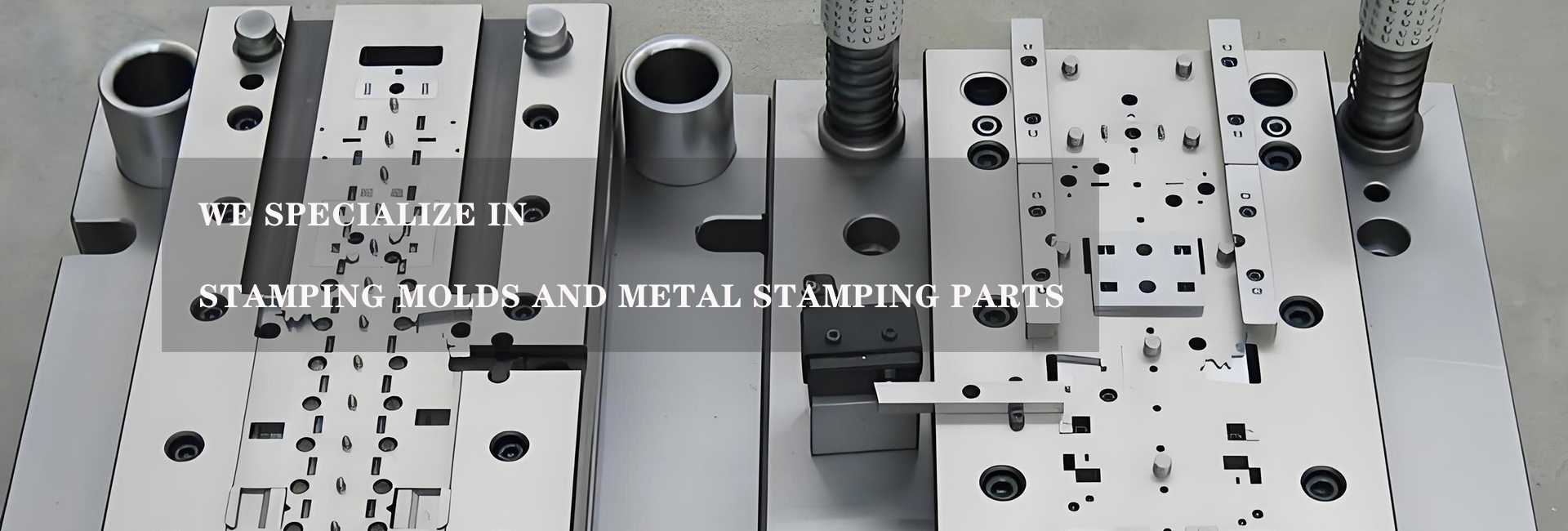

BM MOLDS

which keeps to contribute to our country in terms of employment and

export with the understanding of continuous development by closely

following the developments in the world, aims to be one of the leading

companies in the world in the molding and machinery sector with high

quality and honesty with the Technologies brand... ...

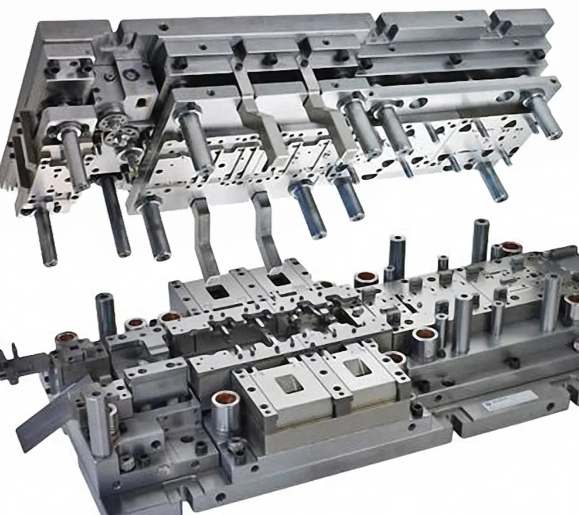

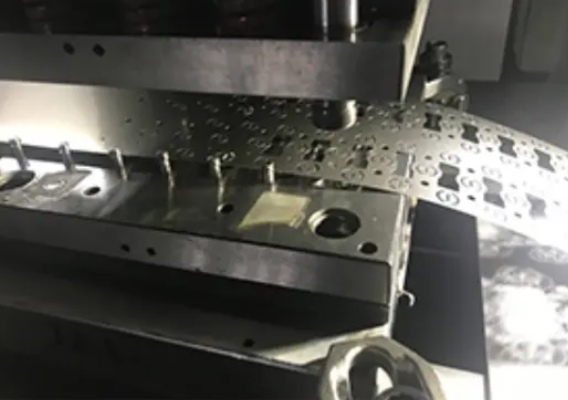

We are a professional mold manufacturing and processing factoryintegrating industry and trade design, production,processing, sales and service. | Our plant covers an area of 3000 square meters, the business scope of stamping die, continuous die, stamping parts processing, CNC machining milling, fixture and station equipment development and manufacturing. | Our company adheres to customer satisfaction, quality first, delivery on time, we are willing to appropriate prices, professional services, and you recommend a long-term friendly partnership. |

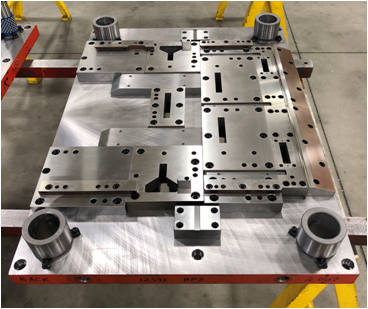

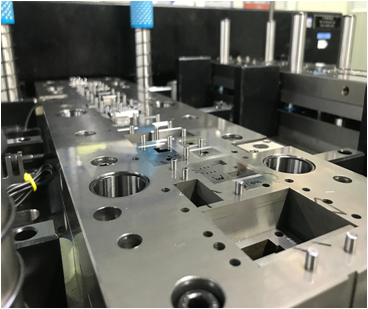

CUSTOMIZE YOUR MOLD

One Stop Mold Manufacturer

CUSTOMIZE YOUR MOLD

Provide 3D model of your design

Send our team the product and/or tooling design geometry by choosing to Get A Project Quote. Your design data will be transferred to our Stamping engineers so we can begin assessing your project immediately.

Demermine a forming process

An initial forming process is simulated. We can develop the entire process independently OR we simulate the tooling data you provided. We review with you every step of the way and your input is always requested.

Engineered with simulation | Results delivered | Structural Simulations |

The forming process is tested with multiple simulations, then re-engineered and simulated until a feasible forming process is developed. | Once we've successfully engineered a forming process, the requested data outputs are generated and sent to you. The solid tooling data and developed blank shapes are provided to you for each forming step. | To stay competitive, meet customer demands, and develop innovative and reliable products in ever-shortening design cycles, designers and engineers require simulation tools that offer best-in-class integrated solutions. |

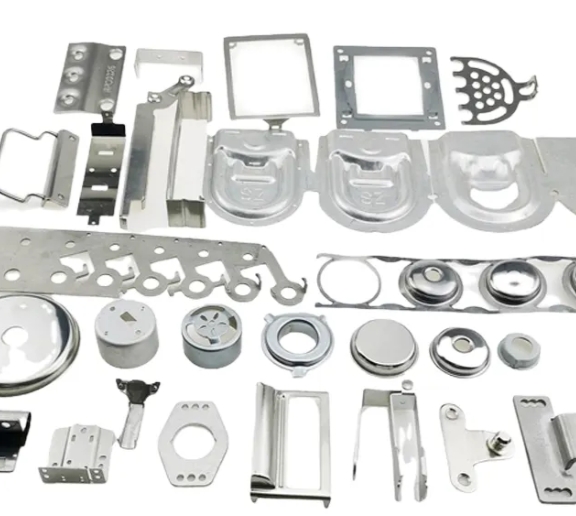

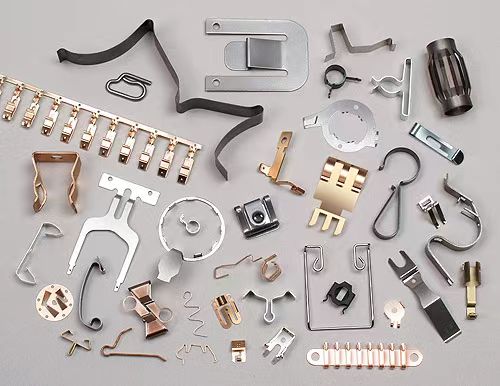

PRODUCTS

PRODUCTS

According to the different stamping molds, these last can be divided into five categories: punching and shearing molds, bending molds, drawing molds, forming molds and compression molds